Tests and controls

Electronics production control and testing: guarantee quality at every stage

Ensuring the quality of your electronic products

In the electronics field, it is essential to differentiate between production checks, which do not require any power supply to the product, and production tests, which require partial or even complete power supply. These checks and tests are carried out throughout the manufacturing process to ensure product quality. In this presentation, we will detail the different tools we use for these checks and tests, highlighting their importance in guaranteeing reliable products.

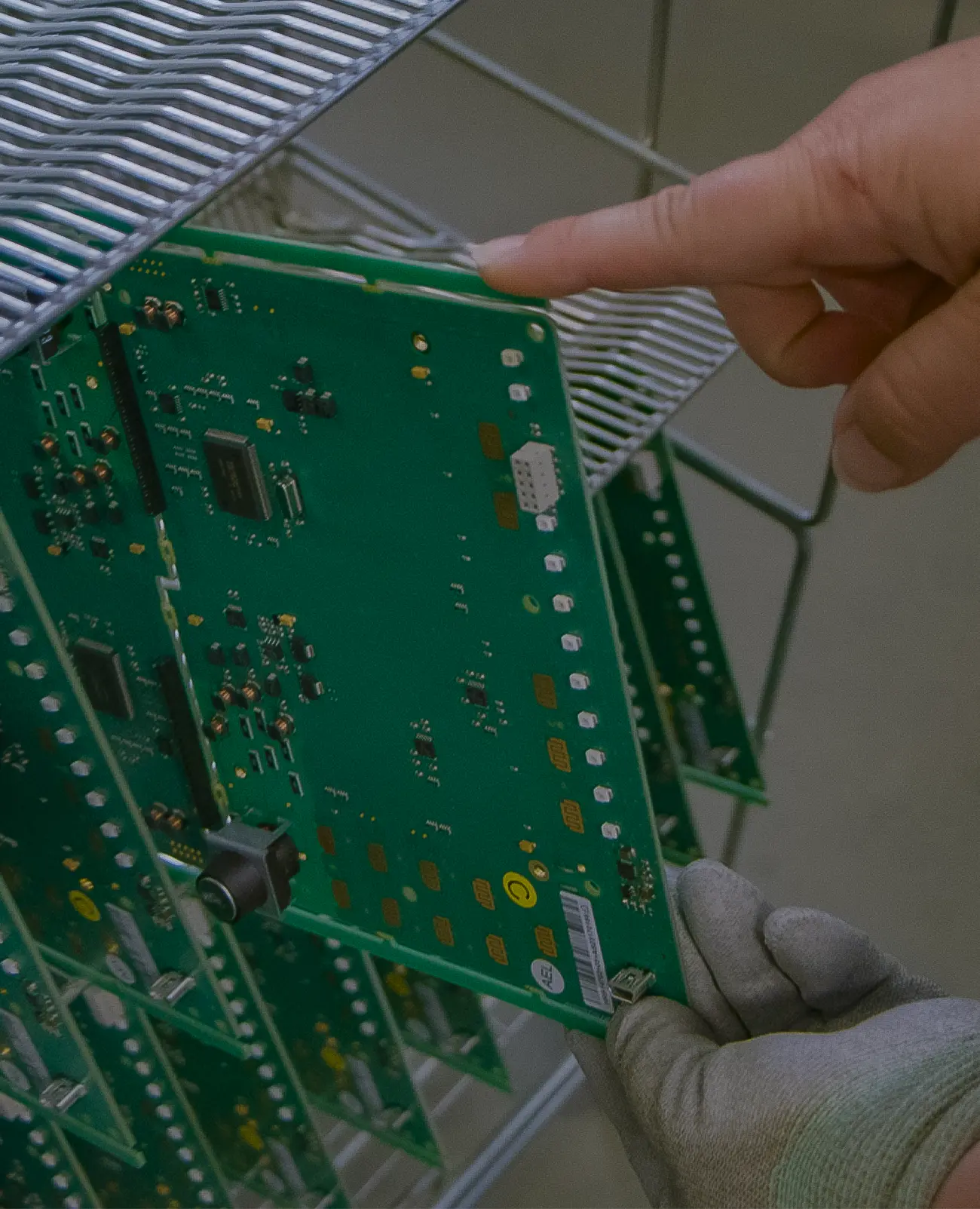

Precise Visual Control with HD IPC-Camera Technology

We carry out a thorough visual inspection to IPC standards, using our HD camera. This technology enables detailed visual inspection, guaranteeing precise detection of any defects or anomalies.

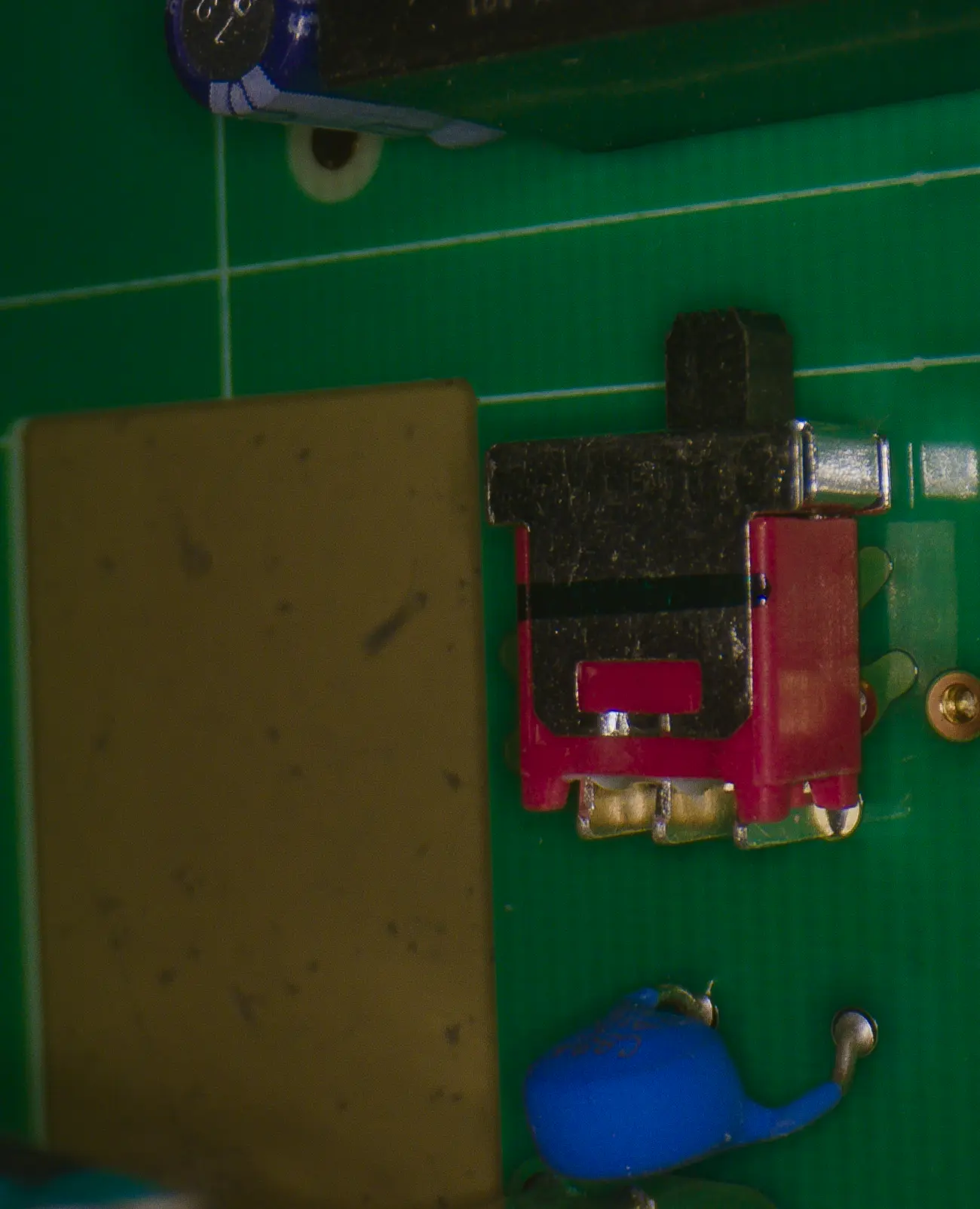

Automatic control with 2D AOI

2D Automatic Optical Inspection (AOI) is an essential tool for production control. It uses sophisticated algorithms to detect faults such as misalignment, weld defects or short circuits. This fast, accurate method improves the efficiency and quality of the manufacturing process.

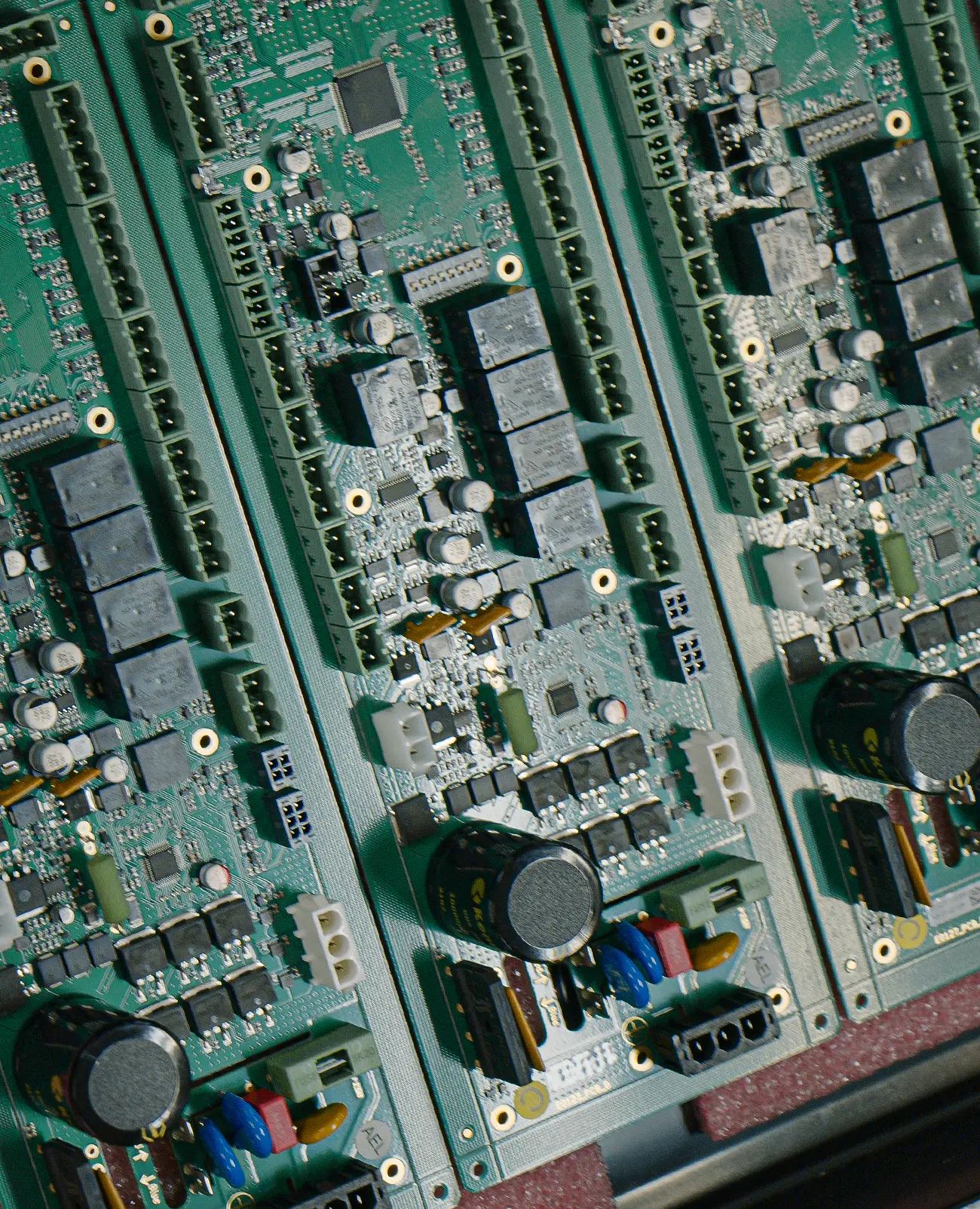

Complete functional and electrical testing

We carry out in-depth functional tests using dedicated test benches and instrumentation racks. This customized equipment, based on national instruments, guarantees accurate and comprehensive electrical testing, enabling us to verify the performance and correct operation of electronic products.

X-ray control for in-depth inspection

X-ray inspection is an advanced technique used for detailed internal inspection of electronic components. It can detect solder defects, voids, flux infiltration and other anomalies not visible to the naked eye. This non-destructive method ensures optimum product quality.

IN SITU and DIEL Isolation tests for full validation

We carry out IN SITU tests to assess product performance under real-life conditions. In addition, DIEL insulation tests guarantee thorough verification of the electrical insulation of components, ensuring the safety and reliability of electronic products.

VRT Burn-in and Ion Decontamination

We carry out VRT burn-in (defined cycle from -30°C to +150°C with power-up), enabling us to detect any malfunctions under extreme conditions. We also use ionic decontamination to eliminate contaminants and ensure optimum product cleanliness.

Conclusion : Expertise in Electronics Production Control and Testing

Electronics production inspection and testing are essential to guarantee product quality. Our range of advanced tools, such as HD camera, 2D AOI, functional testing, X-ray inspection, IN SITU and DIEL testing, as well as VRT burn-in and ion decontamination, enable us to carry out in-depth checks at every stage of the manufacturing process. Rely on our expertise to ensure reliable, high-performance electronic products.

Category:

Date:

June 20, 2023