Pressfit

pressfit connector installation system: Reliability and top quality for demanding customers

The integration of pressfit connectors has become a necessity in the field of embedded equipment, where resistance to vibratory stress is paramount. In this article, we explore in detail the advantages of pressfit connectors, and highlight our connector installation system, specially designed to meet our customers' exacting standards. Thanks to our insertion robot and its advanced features, we guarantee pressfit insertion of the highest quality.

Connector Installation System to Meet Your Requirements

Our connector installation system is designed to meet the needs of even the most demanding customers. Here are the key features of our system:

- Adaptable system for large formats : Our platform handles extended formats up to 1400 x 600 mm and thicknesses up to 8 mm with up to 42 layers. It's ideal for complex projects.

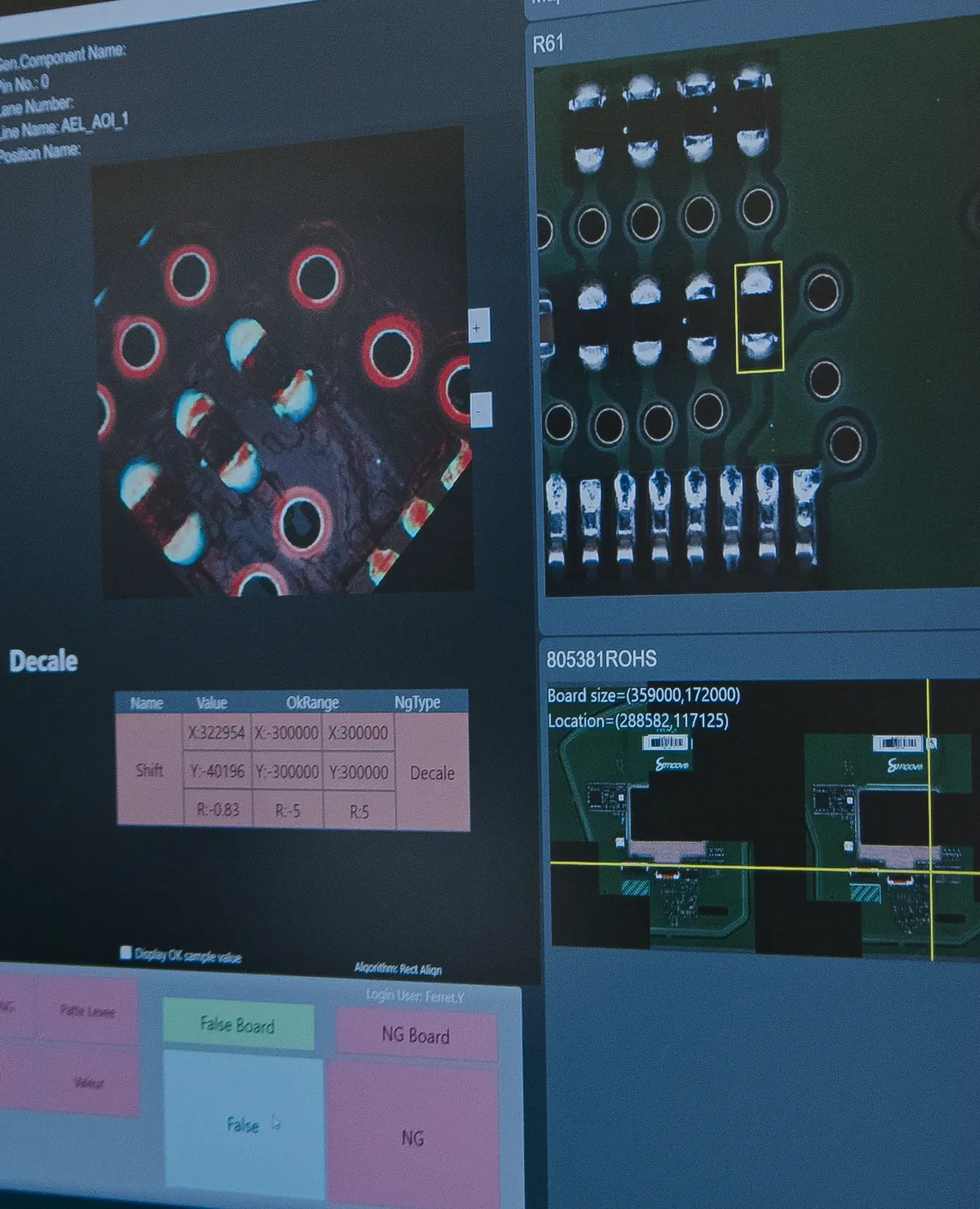

- Control and traceability : Every stage of the insertion process is rigorously controlled and monitored, guaranteeing consistent, reliable quality.

- Computer-Assisted Manual Pressing : Our system offers precise, computer-aided manual insertion for safe Pressfit placement.

- Registering the Insertion Force : The force used during Pressfit insertion is precisely recorded, enabling complete traceability and analysis of results for continuous improvement.

- Component libraries : Our comprehensive component libraries ensure compatibility with a variety of connectors.

- Double-sided and mixed assembly : The system can handle double-sided and mixed assemblies, offering optimum flexibility to meet your specific requirements.

- Multilayer for all thicknesses : Regardless of the thickness of your project, our connector installation system ensures optimal handling of multilayers, preserving structural integrity.

Category:

Date:

June 20, 2023